Contexte et objectifs

A well-known player in the aerospace market, specialising in the manufacture of connecting rods and concerned about the quality and safety of its equipment, was looking for a solution to accurately measure the stiffness of connecting rods in precise, non-planar locations. Requirement

Non-contact measurement of deformation and elongation on large structures to determine Young's modulus and integration of the measured data into the calculation code.

Constraints

- Précision inférieure au micron selon norme ISO 9513

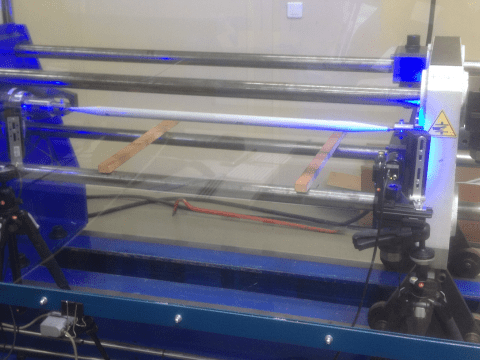

- Mesure sur structure : bielles de 1 à 5m de longueur

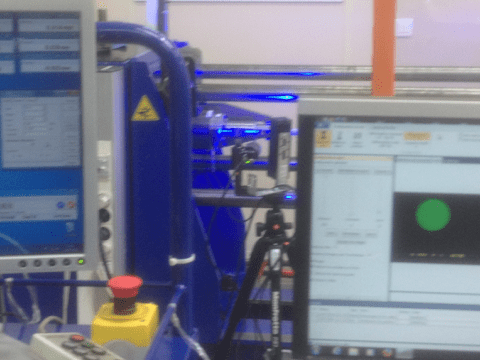

- Intégration à l’existant : machine Zwick, acquisition des données machine (force et allongement de la traverse) et suivi graphique de l’évolution de l’ensemble des données dans le logiciel VidéoTraction.

- Sub-micron accuracy to ISO 9513 standard

- Measurement on structure: connecting rods from 1 to 5m length

- Integration with existing equipment: Zwick machine, data acquisition from machine (force and crosshead elongation) and graphical monitoring of all data in the VideoTraction software.

Solution

The FVX dual-camera version can be used to measure elongation on large parts.