Contexte et objectifs

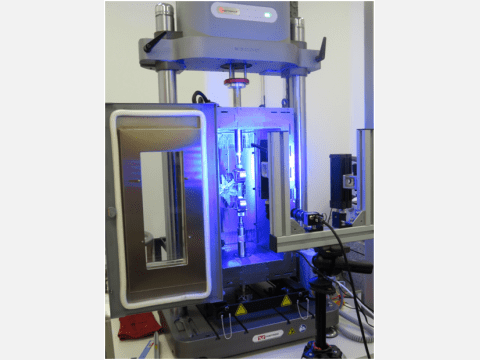

At the request of a laboratory which has developed recognized expertise in the thermomechanical behavior of thin metallic, polymer or composite-based films, we have developed a complete measurement tool. To enable researchers to measure the mechanical properties of materials which are essential for studying the behavior of these materials and multi-material assemblies, particularly under cyclic loading, he wanted to acquire a video extensometry system and complete his experimental equipment. Aims

The requested measurement system had to be integrated at least into the environment of the existing electrodynamic testing machine. It has to measure elongation and deformation in both axial and transverse directions during quasi-static or cyclic mechanical traction or compression tests up to 40 Hz. The system had to make it possible to carry out measurements in two modes, simultaneously or not:

The system also had to be able to control deformation tests and record the measured data via a port available on the machine. The main minimum technical characteristics required were:

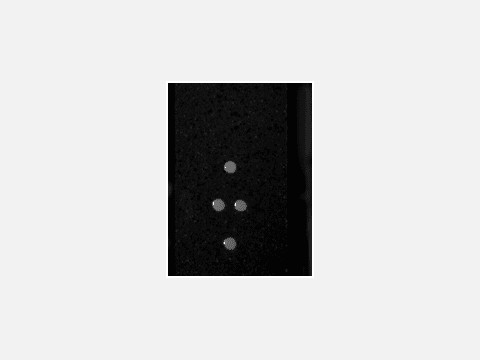

- the axial and/or transverse deformation between two points or four points (which can have a diameter equal to 2 mm maximum) of the specimen in real time during the test (dynamic and quasi-static);

- recording photos of the specimen during the test in order to carry out post-processing later via static and dynamic image correlation software.

The system also had to be able to control deformation tests and record the measured data via a port available on the machine. The main minimum technical characteristics required were:

- a displacement measurement resolution less than or equal to 0.5 µm,

- a precision less than or equal to 0.5% of the value read,

- a sampling frequency greater than or equal to 250 Hz,

- a maximum tracking speed for monotonic tests greater than or equal to 2000 mm/min,

- a maximum tracking speed for cyclic tests greater than or equal to 20,000 mm/min,

- a minimum gauge length less than or equal to 6 mm.

Solution

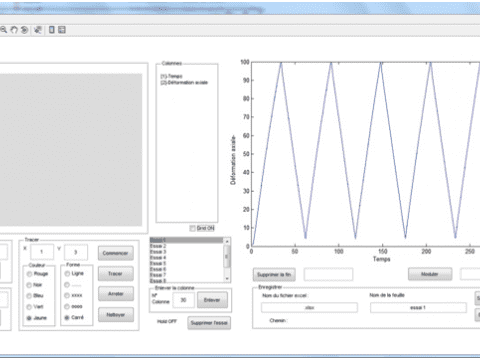

To meet this demand we have developed image recording software with the possibility for the user to be able to adjust the exposure time, the time interval between two shots, stop recording after a duration or a certain number of images, save data in a .csv or txt file containing time, image number, force and an additional channel, and to be able to program a measurement cycle for example 30 min break, 10 minutes of taking photos and so on...

The VideoTraction FVX02 system perfectly met all of the other requirements.

The VideoTraction FVX02 system perfectly met all of the other requirements.