Contexte et objectifs

A company expert in design, manufacturing and maintenance of control valves in nuclear field called on ProViSys to develop a non-intrusive method to check the closure of flaps of various valves installed in a nuclear power plant in order to facilitate staff intervention, but above all ensuring valves tightness before restarting plants.

Aims

- Ensure valves tightnesswhen closing flap

- Facilitate staffmaintenance operations during factory shutdowns

- Facilitate daily security checks

- Save time

- Improve reliability, efficiency and safety

Solution

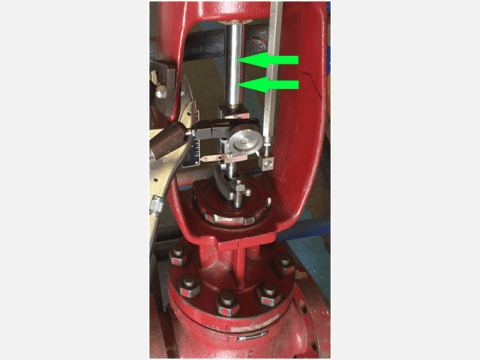

To meet this request we installed version FVX01 of VideoTraction.

Indeed, when flap closes, transmission rod undergoes a compressive deformation of the order of a few microns.

The objective of the system was therefore to be able to detect targets on the rod while overcoming reverberation problems, and to be able to measure a compressive deformation of less than 10µm in an industrial environment.

VideoTraction FVX01 system perfectly met all of the customer's expectations.

Indeed, when flap closes, transmission rod undergoes a compressive deformation of the order of a few microns.

The objective of the system was therefore to be able to detect targets on the rod while overcoming reverberation problems, and to be able to measure a compressive deformation of less than 10µm in an industrial environment.

VideoTraction FVX01 system perfectly met all of the customer's expectations.