Contexte et objectifs

This internationally-renowned French laboratory specialising in the mechanics of materials was looking for a versatile system capable of determining macro-mechanical criteria under different stress conditions (tension/compression, creep, shear, fatigue, etc.) in order to develop behavioural laws for new materials, or to improve existing laws for public or private research, as part of a research contract with the laboratory. Requirement

Improve students' and researchers' knowledge of materials

Establish realistic behaviour laws by taking into account the effects of speed, temperature and deformation of polymer, composite and metallic materials during different stresses:

- Shear with deformation control at constant true shear rate

- Tensile: creep tests at constant stress, measurement of volumetric strain with strain control at constant true strain rate

- Tension/compression: strain measurement in the three directions X, Y and Z (dual camera) with strain control

- Bending: strain measurement in both directions

- Fatigue: detection, monitoring and measurement of crack advance and machine regulation using different control modes (constant K, delta constant K, etc.)

- Coupling with other measurement devices: RAMAN spectrometer, GOM/ARAMIS DIC system, enabling users to obtain data with control of the deformation test using the VideoTraction system.

Establish realistic behaviour laws by taking into account the effects of speed, temperature and deformation of polymer, composite and metallic materials during different stresses:

- Shear with deformation control at constant true shear rate

- Tensile: creep tests at constant stress, measurement of volumetric strain with strain control at constant true strain rate

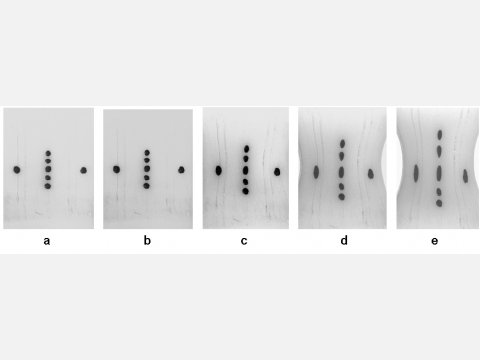

- Tension/compression: strain measurement in the three directions X, Y and Z (dual camera) with strain control

- Bending: strain measurement in both directions

- Fatigue: detection, monitoring and measurement of crack advance and machine regulation using different control modes (constant K, delta constant K, etc.)

- Coupling with other measurement devices: RAMAN spectrometer, GOM/ARAMIS DIC system, enabling users to obtain data with control of the deformation test using the VideoTraction system.

Constraints

- Intégration à l’existant (ancienne machines hydraulique MTS et Intron 8500) et parfaite synchronisation des données (force, déformations, déplacement traverse),

- Pilotage total des machines en déformation et en force ce qui suppose une parfaite connaissance et maîtrise de l’environnement de la machine

- Essai en température dans un environnement critique

- Integration with existing equipment (old MTS and Instron 8500 hydraulic machines) and perfect synchronisation of data (force, deformation, crosshead displacement),

- Total control of machines in terms of deformation and force, which presupposes perfect knowledge and control of machine environment.

- Temperature testing in a critical environment .

Solution

Dual camera FVX DEV version + Shear jaws