VidéoTraction eXpert

VidéoTraction® : l'origine

Usually, materials mechanical properties characterization mode, and in particular polymers, is standardized tensile test, at constant elongation rate: a test piece (standard dimension part) is stretched uniaxially until it breaks.

Since the beginning of the polymers discovery, all tests have been carried out according to this protocol.

However, we realize that notions of nominal deformation and stress have no meaning for the MATERIAL.

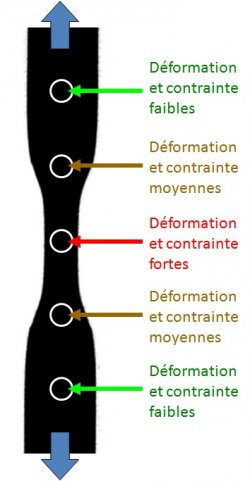

In a specimen deformed after necking appearance, the strain and stress vary from one point to another.

It is therefore important to adopt local definitions of mechanical variables:

- TRUE DEFORMATION

- TRUE STRAIN

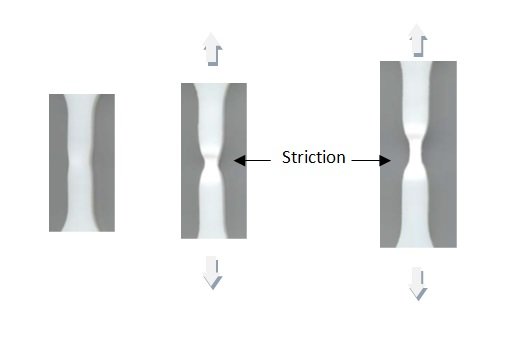

Indeed, a necking phenomenon appears after elastic limit (moment from which material begins to deform irreversibly): deformation is localized in a limited zone whose section is increasingly reduced while the rest of the test piece practically does not deform. The deformation speed is therefore greater there than in the rest of the specimen, and undergoes large variations (up to 100 times the overall speed).

Thanks to the VideoTraction® measurement system developed at the end of the 1980s by Prof. Christian G'SELL and Jean Marie HIVER, we impose a traction machine regulation in such a way that local deformation speed (at the center of the necking) remains constant, which makes it possible to connect the deformation and the stress in real time taking into account sample geometric evolution.

Thanks to the VideoTraction® measurement system developed at the end of the 1980s by Prof. Christian G'SELL and Jean Marie HIVER, we impose a traction machine regulation in such a way that local deformation speed (at the center of the necking) remains constant, which makes it possible to connect the deformation and the stress in real time taking into account sample geometric evolution.